One of the initiatives on the sidelines of this year’s Foiling Week in Malcesine on Lake Garda that attracted a lot of interest from the top sailors present was the launch by Gottifredi Maffioli, the manufacturer of nautical ropes, of a small titanium object with a spliced rope: the TitAelium. Its main purpose is to reduce windage.

This little trapeze rope cleat has a true grand prix racing pedigree. TitAelium was developed by Ruggero Tita – a double Olympic gold medallist, helmsman of the Red Bull Italy SailGP Team and also the helmsman of Luna Rossa for the upcoming America's Cup campaign.

At the product launch event at Foiling Week, elite professional sailors such as Diego Botín, Tom Slingsby, Paul Goodison, Sime Fantela, Phil Robertson and Iain Jensen, to name but a few of those present, were finally able to get their hands on this beautiful, finely crafted gem weighing just 18 grams.

Until then, TitAelium had only been a prototype that Tita had used while winning his second Nacra 17 Olympic gold medal with Caterina Banti in Marseille. Now Gottifredi Maffioli, working in partnership with Tita and Trentino Sviluppo’s ProM Facility, is making it available to all sailors whose boats require the use of a trapeze.

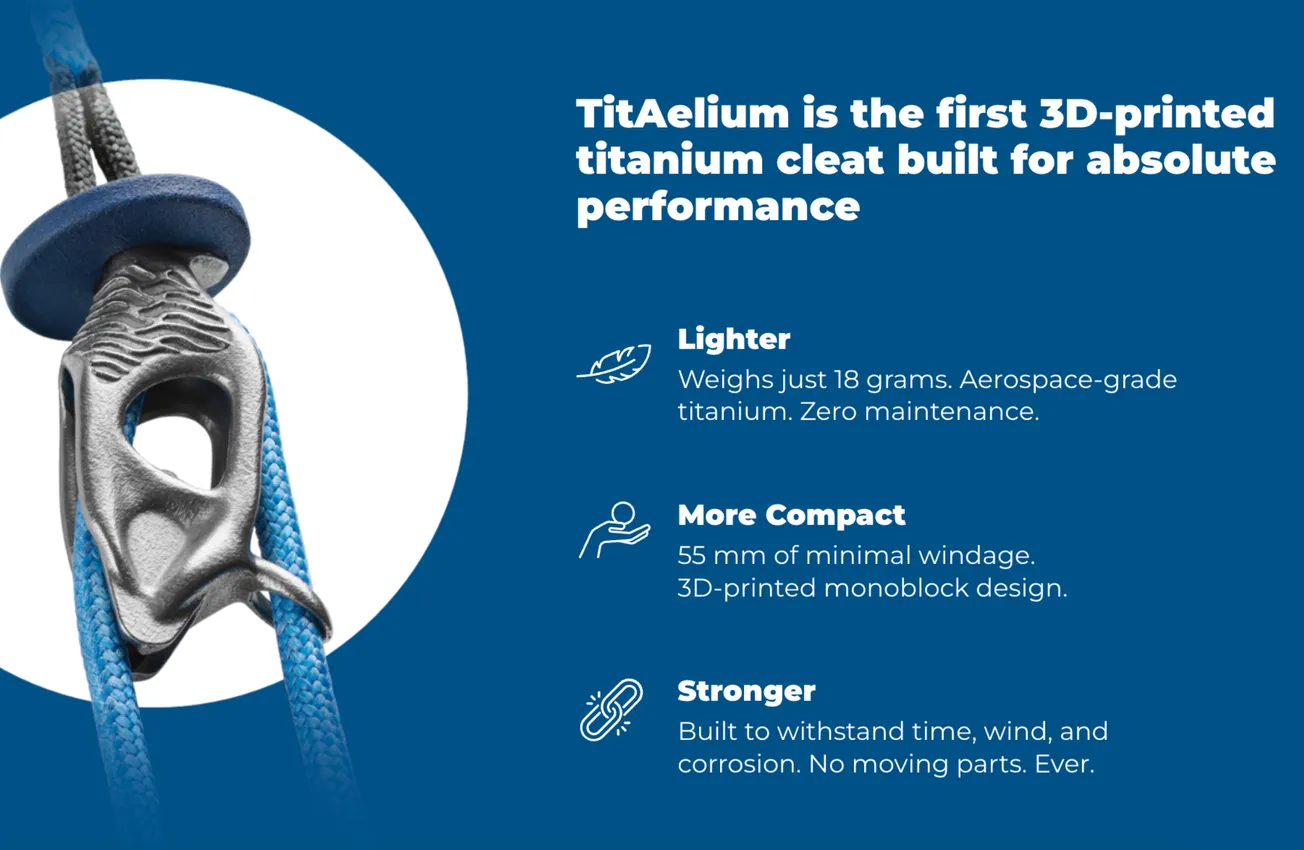

TitAelium is a groundbreaking cleat designed to reduce both weight and aerodynamic drag. Aero drag has become a significant factor in recent years due to the ever-increasing speeds of modern high-performance dinghies.

The titanium construction guarantees exceptional durability and helps to make the system extremely compact, light and corrosion resistant. The cleat is made from an aerospace grade titanium alloy (Ti6Al4V) using an advanced 3D printing process based on L-PBF (Laser Powder Bed Fusion) technology, which allows extreme precision in manufacturing.

TitAelium is a monobloc structure with no moving parts. This ensures maximum corrosion resistance, zero maintenance and minimal aerodynamic drag. Weighing only 18 grams and measuring a compact 55 x 12.5 x 27mm, its surface has an ergonomic texture designed to provide a secure and comfortable grip.

Lamberto Cesari, the project manager at Gottifredi Maffioli for this initiative, is a sailor with extensive international dinghy racing experience, particularly in sports catamaran classes.

‘We are very pleased with this result and with the unique partnership that has developed between Ruggero and ProM Facility,’ said Luigi Maffioli, technical director of Gottifredi Maffioli. ‘As a company we are often involved in product development projects as an interface between designers and sailing teams. Over the years we have increasingly become a platform for innovation in textile solutions, leading to design improvements.

‘We have always worked with the best Olympic sailors on rope development projects. TitAelium represents the next generation of combined hardware and textile solutions. We are proud that the world of Olympic foiling dinghies is driving us forward.’

Ruggero Tita, who has been working with Gottifredi Maffioli on product development in the Olympic classes since 2015, explained his approach to preparation: ‘My idea has always been not to overlook any detail of the boat. Every little thing you can add, remove or improve is something that will give you an advantage in the race, even if it's a small one that, when added to the others, gives you something more. When races are decided by three or five metres, small margins become crucial.

‘With one-design boats, like the 49er I started with and the Nacra 17 catamaran, the areas where modifications can be made are very limited.

‘Trentino Marketing, the regional development agency of Trentino-Alto Adige province, is one of my sponsors. They put me in touch with Trentino Sviluppo and the ProM Facility, which is its mechatronic prototyping subsidiary.

‘We started with the mainsail block and tackle in 2020. After the Tokyo Olympics we focused on the trapeze cleats because this is an area where we can work to reduce drag, considering that there are four exposed cleats on the Nacra 17.

‘We started with the pulleys, first in plastic and then in metal, and carried out numerous tests and iterations until we arrived at the final product, which has been greatly simplified to ensure durability.’

‘This is an important milestone for ProM, as we are launching a product for commercial production and distribution for the first time,’ said Paolo Gregori, director of the ProM Facility.

‘Even more significant is the fact that a gold medalist Olympic athlete like Ruggero Tita has chosen to share with the public a solution designed to win.’

TitAelium is supplied complete with a high-performance rope. The line is a 2.5mm-diameter DSK78 Novabraid, with a 1 x 1 x 24 M Dyneema cover. The rope is finished with a covered eye splice, to be cow-hitched onto a trapeze ring. It will be available for purchase on the website.