When you ask the lead designer at Cariboni what the biggest challenge was in creating the hydraulic systems for the new 32m maxi Magic Carpet-e, the response from Pierluca Bertolotto comes instantly.

‘The keel,’ he says. ‘It wasn’t just the size, we’re used to that with maxis like Comanche and Skorpios, but to build a canting keel system that lifts like a dinghy centreboard to take it from 7.1m to 4.6m while the keel bulb also swings to remain horizontal, made this project very challenging.

‘To have this much articulation made the Magic Carpet system complex. Plus, we also had the pressure of achieving quite tough performance targets while keeping the weight down.’

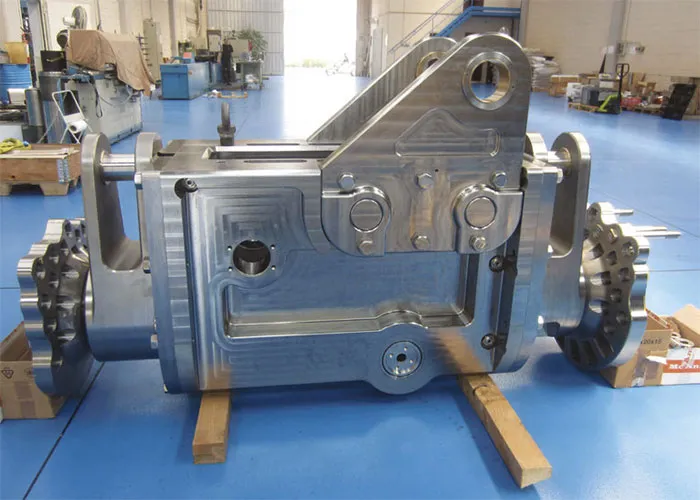

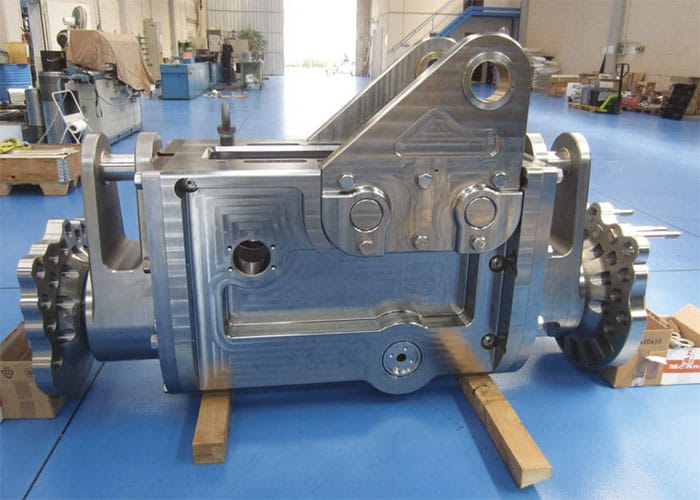

For all the numbers and technical details of such a sophisticated piece of equipment, the reality hits home when you see the keel mechanism in the flesh. The huge titanium cassette that supports the keel fin in the hull and provides the articulation is a work of art that took four months to machine from solid.

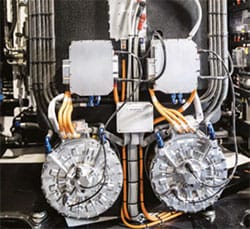

1. Main image: It took four months to machine the titanium cassette that supports the keel fin and provides the articulation. | 2. Cariboni’s hydraulic systems can be found aboard many of the world’s most advanced raceboats.

This is a world that Cariboni know well. Acknowledged experts in the field of marine hydraulics, their systems can be found aboard many of the world’s most advanced racing machines, from TP52s through maxis and Imocas to America’s Cup boats and beyond, into the superyacht world. And while the projects are frequently at the leading edge of design, the challenges and lessons learned from them provide the knowledge and expertise to create new systems and techniques.

‘While we were building the systems for Magic Carpet-e, we were heavily involved with the America’s Cup and the teams’ AC75s,’ says Paola Cariboni. ‘The America’s Cup is not just a technical challenge, it also provides invaluable feedback from the teams every day as they test, experiment and develop their systems and techniques. And while much of the information is confidential, everyone is learning fast and the technology is evolving rapidly.’

For Bertolotto, the potential benefits that result from the America’s Cup to the rest of the sailing world are clear.

‘The intensity with which hydraulic systems on Cup boats operate means that components can wear out very quickly as the number of actuations are so high,’ he says. ‘Hydraulic seals in areas like the mainsheet traveller can be a problem as they don’t like working at high speed, so we needed to find ways of accommodating this. The benefit to cruising yachts and superyachts that don’t need to operate at such high intensity is that their systems can now be made more reliable. Plus, many of the systems that we develop at maxi or Cup levels can be scaled down to 40-footers.’

Not all projects need components milled from titanium either, as Paola Cariboni explains.

‘Sometimes there is no need for titanium or stainless steel when you are producing smaller components for a different environment,’ she says. ‘When the loads are lower, aluminium is often the best material for cost and weight.’

Cariboni’s involvement with Magic Carpet-e was extensive, as there is a total of 31 hydraulic rams on board. In addition to this, the company supplied the headsail furlers too. Once again, with a maxi that was designed to compete at close quarters, around the cans where the 100-footer needed to be as nimble as a racer less than half her size, this project took design and technology into new areas once again.

‘The furlers are completely new,’ says Bertolotto. ‘Not the concept or the sizes, but the amount of torque that they develop and the speed that they operate at. The rig is different from a normal maxi and they use the furlers a lot more which again puts pressure on the design and manufacture. In fact, on Magic Carpet 3 they used to take the furlers off for racing, so this is a very different proposition.’

On any of these sophisticated machines, be they America’s Cup boats or leading edge maxis and superyachts, there is one area where the demands are especially high: delivering the oil pressure to run them. Here the correlation between the number of hydraulically driven devices, their operating speeds and the specific moments when they will be required to operate frequently puts huge demands on the delivery of hydraulic oil pressure.

‘It is not unusual for us to be negotiating with yacht racing teams as to the capacity of oil that is required on board,’ says Paola. ‘We might be suggesting say 400 litres of oil, while the team might be trying to keep the weight down and looking for significantly less volume yet still maintaining the same loads and operating speeds. And at the end of the day, on some of the most advanced racing boats out there, it often comes down to how many people are pushing buttons at the same time.’