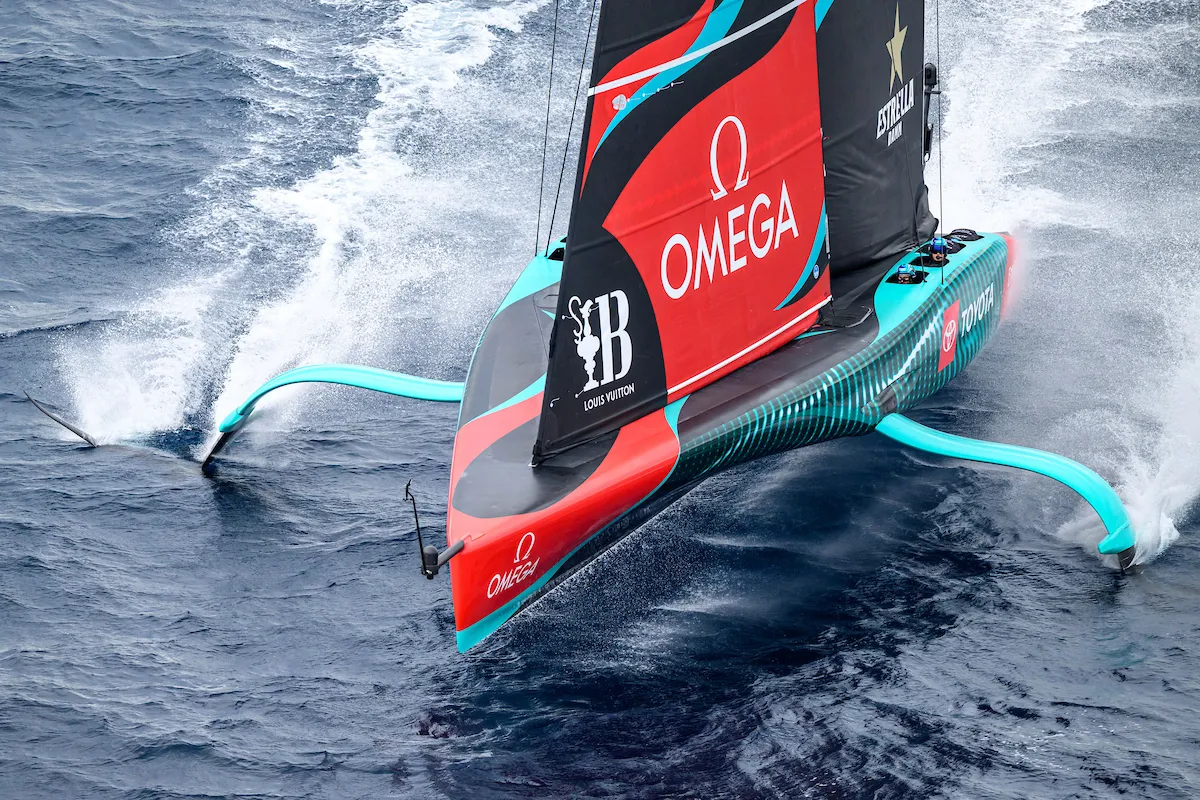

That may be the case with foils, flight control systems, double-skinned mainsails and many other areas. But some technologies are exactly the same, be they on an America’s Cup boat or an around-the-cans racer. As B&G product director Matt Eeles explains: ‘in the last America’s Cup, every team had a B&G wind sensor’.

‘These units were exactly the same as those used on thousands of raceboats and blue water cruisers. And when you think of how speeds have increased lately that’s pretty impressive. Until recently, the typical high apparent wind speed that boats might be regularly measuring would be, say, 30 knots, but today the Cup boats are seeing 50-60 knots on a regular basis, yet they are still needing to make the same calculations for true wind angle and speed.

‘Whether you are racing or cruising there are four fundamental measurements for any instrument system: boatspeed, heading, wind speed and wind angle,’ Eeles says. ‘These are the absolute basics on which a raft of other calculations and applications depend. Of those four basics, wind measurement accounts for 50 per cent, which makes it easy to see why the anemometer is so important.’

B&G has always set out to produce the most accurate instruments and in 2018 the focus was on refreshing its range of wind sensors, introducing what are now the WS300 (horizontal wired and wireless) and WS700 (vertical, varying lengths) units.

B&G started with a detailed study of anemometer performance using the wind tunnel at Southampton University. ‘We looked at a wide range of units including those of our competitors,’ Eeles continues. ‘We were looking at a number of factors from the basic performance and whether their output was linear across a range of wind speeds, to their accuracy when subject to roll, heel and pitch. We were also looking at issues like the flutter of the wind vane, the inertia of the vane, the speed at which the anemometer cups would accelerate along with other factors.

‘Understanding all of this is really important. For example, when boats heel, the wind angle at the top of the mast tends to reduce so this needs to be corrected to ensure a consistent reading.

‘The wind tunnel research allowed us to design spinning cups and wind vanes that were mechanically as accurate as they could be. From there we could then make mathematical corrections for the induced errors such as the change in wind angle with heel.’

Having the most accurate input then allows a raft of other instrument functions to perform at their best. From navigation models to autopilots, it’s easy to see where the benefits may lie. But there have been other, less obvious advantages.

‘Accurate input data has made it easier to solve issues elsewhere in system development,’ says software engineer Alex Adams. ‘It also makes it easier to develop calibration wizards that make the onboard set up simpler and more accurate for the user.’

Refining the data doesn’t stop at the masthead. With B&G’s system, making sense of the numbers measured at the top means processing them at the bottom. ‘We then correct the wind angle and wind speed for static heel and trim prior to gyro correction for roll and pitch rates, using a motion sensor. We always measure this around the centre of rotation, which means the bottom of the mast. Because we know the mast length, it's effectively like a reverse pendulum type calculation,’ Eeles continues.

‘Then we use our sailing processor, which takes all of those inputs and combines them with wind data to make the corrections. And it’s this that feeds the true wind calculations, which then potentially provide stable and accurate true or apparent wind angle information for your autopilot.’

Then there’s the need to protect the system from electromagnetic issues, especially in electrical storms. B&G’s wind sensors all pass strict electromagnetic compliance testing for immunity and radiated emissions. They are also certified for 8kV electrostatic discharge and have passed EU automotive tests at 30kV to simulate static discharges from near lightning strikes.

So, while the wind vane and anemometer might look like a straightforward piece of kit, it’s probably the only product on an AC75 that a consumer can buy in their local chandlery or dealer.