Every now and then, a yacht begins not with a design brief, but with a question. In the case of the PB72, it started in the middle of the Pacific Ocean. During the 2015 Transpac Race, a legendary offshore sprint from Los Angeles to Honolulu, known for its fast passages and trade wind surfing. But for Patrick Benz, owner and sailor of a Gunboat 66, that particular race became more than just a performance benchmark. That race, and the hundreds of hours of performance sailing that preceded it, planted a vision in Pat’s mind – one that would evolve into one of the most technically ambitious multihulls we've ever developed at Morrelli & Melvin.

Midway through the race, flying downwind aboard his sleek catamaran, Pat was struck by the limitations of the foiling systems then in use. The C-shaped foils on his Gunboat offered lift, sure—but they were inherently a compromise. The curved design generated both vertical lift and lateral force at once, a coupling that made control more complex. What if, he wondered, those forces could be separated? What if you could decouple lift and leeway resistance, and do it all on a luxury cat designed not only to race, but also to live on?

That question echoed through the years that followed. It became a design brief, then a mission. And ultimately it became the PB72 – a 72ft semi-foiling performance catamaran that pushes beyond the boundaries of conventional multihull design.

Reimagining performance

From the outset, the PB72 was never meant to be an iteration. At Morrelli & Melvin, we approached this project as a clean-slate opportunity to explore what’s possible when high-performance design tools, advanced hydrofoil systems and offshore capability all converge. Our objective wasn’t to create a full-foiling machine suited only to narrow wind bands. It was to develop a next-generation platform capable of sustained, high-speed sailing in the real world.

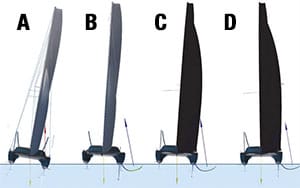

A major step forward came in the foil configuration. Traditional curved daggerboards like those we used on earlier performance catamarans provide both lift and lateral resistance – but by combining those forces into a single element, you sacrifice precision and control. With the PB72 we opted to separate the tasks: straight high-aspect daggerboards handle leeway resistance; T-rudder foils with elevators manage pitch and directional stability; and the righting moment foils (RMFoils) generate vertical lift and massive righting moment – up to 180 per cent more – allowing the yacht to ride higher and faster while staying firmly under control.

This setup allows the PB72 to operate in a semi-foiling mode, optimised for 70–90 per cent lift. Unlike the full foilers seen in the America’s Cup, where yachts fly completely free of the water, we deliberately chose a configuration that retains some hull contact to maximise stability and control. In ideal conditions the PB72 is capable of full foiling but that’s not her mission. Our goal was always to deliver consistent performance across a wide range of wind angles and speeds, especially offshore.

One of the challenges with any foiling configuration is balancing performance in light air. Foils that deliver lift at 18+kts of boatspeed can become a drag liability below 12. To overcome this, we designed the RMFoils to be fully retractable. When retracted, the vertical daggerboards serve as the primary foils, optimised for light-air efficiency and low drag. This retractability gives the PB72 genuine versatility across a range of conditions, ensuring performance is preserved whether you’re blasting downwind in 20kts or racing in seven knots of wind.

A toolbox for innovation

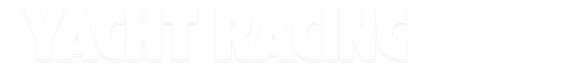

Designing a yacht like this requires you to sling out the textbook. The concepts don’t exist in old drawings or handed-down rules of thumb. Instead, we relied on modern simulation tools like Gomboc, a dynamic VPP platform developed by SumToZero and used by Emirates Team New Zealand. With it, we could test and refine every detail – foil shapes, hull shapes, sail configurations – in a dynamic, digital ocean. Gomboc allowed us to take a leap in the iterative design process. It became our tank and wind tunnel, our racecourse, and our sketchpad. Through thousands of simulations we refined not only how the PB72 sails, but how it behaves in every mode: racing or cruising, reaching or punching upwind in messy seas.

Originally, the call was to shoot for a 50 per cent lift fraction - enough to reduce wetted surface and improve performance without overcomplicating the platform. But thanks to the precision and fidelity of our design toolbox, we quickly discovered that a 100 per cent lift fraction was not only possible, but viable on a cruisingperformance catamaran platform. By carefully refining foil geometries through simulation, we unlocked full-foiling potential in a yacht built also for cruising.

The results speak for themselves. In cruising mode, the PB72 sails effortlessly at 12kts upwind and 25kts reaching. In race mode, with the RMFoils deployed and a sharp crew on the handles, she’ll do 26kts upwind and 40-plus downwind. What makes this even more remarkable is that the PB72 doesn’t require an elite team to operate. While offshore racing demands a seasoned crew of eight to nine, she’s fully manageable for a shorthanded team during day sails or high-delivery trips. In light air or big breeze, the skipper has options: traditional sailing or full foiling and everything in between.

About Morrelli & Melvin Engineering

Morrelli & Melvin Design and Engineering is a renowned naval architecture and engineering firm based in California, specialising in the design of high-performance multihull and monohull vessels. Founded by Gino Morrelli and Pete Melvin, the firm is globally recognised for its innovative approach to yacht and powerboat design – particularly in hydrofoil technology, advanced composite construction and high-speed performance systems.

Over the years, Morrelli & Melvin has been a key contributor to groundbreaking projects ranging from America’s Cup campaigns to recordsetting offshore racing yachts. Their expertise spans the full spectrum of design and engineering: from concept development and structural analysis to performance optimisation and production support.

Ferdinand van West, a naval architect and partner at the firm, has been with Morrelli & Melvin for over a decade. He has played a leading role in many of the firm’s most ambitious projects, from project-managing the introduction of the Olympic Nacra 17 class to co-leading foil design for American Magic in the 37th America’s Cup. Ferdinand brings a unique blend of design, engineering, and on-thewater racing experience. He is also a well-accomplished sailor, most notably having won two world championships in the Formula 18 catamaran. His multifaceted expertise ensures that Morrelli & Melvin remains at the forefront of high-performance yacht innovation.

Principal dimensions of the PB72

Length overall (LOA): 21.95m

Beam overall (BOA): 9.50m

Air draught: 37.00m

Light displacement: 20,500kg

Sail plan: Mainsail – 220m², J3 – 95m²

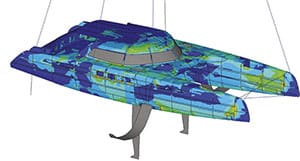

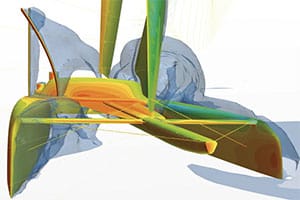

Clockwise: 1| The PB72’s RMFoils require a precise insertion point through the deck. 2| FEA map showing structural stress distribution across the hull and deck under simulated load conditions. 3| A: Displacement sailing (Red Arrow), with RMFoil retracted. B: Upwind semi-foiling with 80% lift fraction. C: Downwind semi-foiling with MH0, 80% lift fraction, windward hull flying. D: Downwind semi-foiling with MH0, 80% lift fraction, windward hull skimming the water, leeward hull lifted clear. 4| Aero flow visualisation developed by M&M to optimise the yacht’s platform architecture. 5| The master cabin, one of three doubles. 6| Daggerboard case and RMFoil case.

The interior challenge

Below decks, we faced one of the project’s more complex design challenges: integrating a high-performance foil system into a refined, ergonomic interior that could meet the owner's high expectations for comfort and style. While our primary focus was on the structural layout, we later brought Design Unlimited on board - not only to optimise functionality but also to deliver a sleek, modern aesthetic that elevates the entire experience.

The RMFoil cases, where critical load paths converge, had to traverse living spaces without compromising structural integrity or usability. Unlike centerline daggerboards, which can be discreetly tucked away, these outboard foils extend diagonally through the hulls. Precise spatial planning is essential both above and below deck. The rondure (foil curvature in the front view), in particular, had to satisfy strict clearances for sailing operations in all modes while staying within the yacht’s high-maximum beam limits for docking.

This complexity meant that the interior layout couldn’t be finalised until the design geometry was fully resolved. Bulkheads, cabinetry, passageways – even window placements – were sculpted around the foil trunks. All details had to accommodate both the static structure and the dynamic movement of the foils without disrupting ergonomics. The owner’s passion for interior comfort drove us to go further: he envisioned a galley that was as much a performance workspace as it was a place for relaxation. It even features a beer tap - an offbeat touch that brings a bit of levity to serious offshore sailing.

The cabins uphold this high standard as well, being fully equipped and fitted with air conditioning to ensure luxury comfort during long passages offshore. Through careful design iterations and digital mockups, we achieved an interior that not only meets rigorous performance criteria but also delivers a distinctly stylish and inviting environment. It’s one of the most integrated and thoughtfully styled interiors that we’ve ever delivered on a performance multihull.

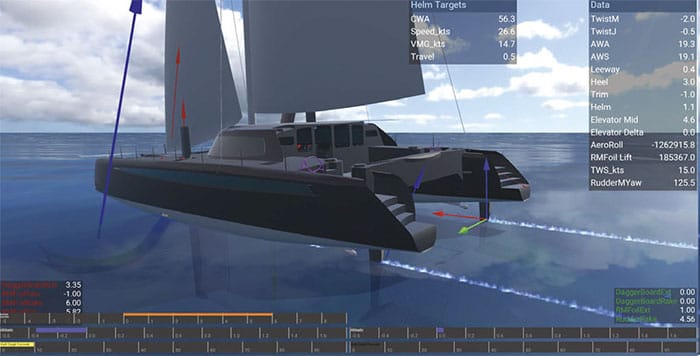

We also recognised that the exterior shape above the waterline was key to the platform’s overall performance. Integrating the cabin top and underwing into a seamless, aerodynamically efficient shape was akin to designing the fuselage of an aeroplane. While aesthetics remained critical, our emphasis was on aerodynamics and functionality. The result is the slick teardrop design of the cabin top that not only enhances the yacht’s visual appeal but also reduces drag and improves overall efficiency by integrating the sails and hull into one optimised aerodynamic package.

Structural design: balancing strength and weight

Structurally, the PB72 is built to the highest standards in the game. Constructed at Persico Marine entirely of prepreg carbon fibre with a Nomex honeycomb core and foam-cored elements in high-impact areas like the bows, every component is engineered for an optimal strength-to-weight ratio. We used Finite Element Analysis (FEA) to map stress and strain distributions across the composite laminate structure, informing everything from laminate schedules and bulkhead placement to the reinforcement of foil cases and the optimisation of load paths. Kurt Jordan led the structural FEA analysis in close collaboration with our Morrelli & Melvin team, carefully developing the critical load cases in conjunction with North Sails and Southern Spars. We combined our stateof- the-art simulation tools with traditional load case standards from the ISO multihull rule to validate the design’s integrity.

By selecting intermediate modulus pre-preg carbon fibre for the primary structures and employing advanced vacuum techniques to achieve high fibre-to-resin ratios with optimal curing conditions, we ensured that the hulls, beams and foil structures can withstand both the steady loads of cruising and the extreme forces generated at speed. Note that the light ship weight – approximately 19 tons – is measured without the RMFoils deployed, while the vessel weighs around 22.5 tons in full race mode. The PB72 remains lean yet exceptionally robust, ready to push the limits.

Advanced systems

Our foil control systems were designed and engineered in-house at Morrelli & Melvin, with the hydraulic actuation systems developed by CCHE. The RMFoils use passively adaptive, surface-piercing geometry to manage lift dynamically, but to fully unlock their potential we needed a control environment that could match their complexity without overloading the crew.

The PB72 uses a hydraulic foil actuation system managed by a PLCbased automation platform - a Programmable Logic Controller, built for precise, high-speed control in demanding conditions. We collaborated with Emirates Team New Zealand to integrate their proven PLC infrastructure from the America’s Cup.

The foil control system interfaces with SumToZero’s “Blogger” autopilot software, which uses the same physics engine as Gomboc, the dynamic VPP simulator we used during the yacht’s design and performance development. That continuity from simulation to real-world control creates an unusually tight feedback loop between virtual testing and the boat’s actual on-the-water behaviour.

To round out the performance systems we integrated a hybrid propulsion and power generation package from Torqeedo. The PB72 uses a system very similar to their standard Deep Blue Hybrid system, which not only delivers efficient electric propulsion but also supplies power to onboard systems, including the hydraulics used for foil control and sail handling. It’s a lightweight, reliable and silent system when needed.

Collaboration across disciplines

No project of this scale is completed in isolation. We partnered with some of the industry's top players to bring the PB72 to life. Malcolm Park served as the project manager and owner representative, providing the technical and logistical expertise needed to coordinate our multicontinental team. We worked closely together, ensuring that design intent and engineering execution remained aligned through every phase of development.

The yacht has been constructed by Persico Marine in Italy, a shipyard renowned for its precision in carbon composite builds. Southern Spars supplied the highaspect rig and their design team worked hand-in-hand with Morrelli & Melvin to ensure the rig geometry, sail handling systems and structural integration aligned with the yacht’s unique performance envelope. North Sails took the same collaborative approach, tailoring the sail wardrobe specifically to the PB72’s foilassisted dynamics and aerodynamic targets. Their aerodynamic sail data models were directly integrated into our simulation tools, ensuring that the rig designers and sail designers were working from the same baseline.

We also involved our friends at Pure Design & Engineering for the detailed engineering of the RMFoil and control hardware. Their experience in particular with Imoca 60s was instrumental in defining load cases and how far we could push the limits.

Emirates Team New Zealand contributed with an advanced rudder rake system, along with PLC software programming and autopilot logic derived from their America’s Cup experience. Finally, American Magic is playing a key role in commissioning and early sea trials, validating performance targets and helping fine-tune critical systems.

Commissioning and what comes next

As I write this, the PB72 is entering its final commissioning phase. We’re working closely with the American Magic team who are some of the most experienced professionals in the world when it comes to high-speed, foiling platforms. Their input during sea trials will be invaluable as we dial in the systems, tune the ride and prepare her for debut.

But more than anything we’re excited to see Pat’s vision come to life on the water. For five years he’s been the driving force behind this project, always pushing us to go further, refine more and dream bigger. His dream? To sail this yacht in offshore races like the Transpac, cook a proper dinner at 30kts and maybe open a cold beer as the foils hum beneath his feet. In a way, it’s a dream we all share.

Because for us designers, yachts like the PB72 don’t come around often. They’re more than just projects. For us, the PB72 represents a kind of convergence. It fuses the lessons we’ve learned from decades of multihull design, from the Gunboats and HH Catamarans to the America’s Cup. It blurs the line between sport and cruising, between comfort and adrenaline, between concept and execution.

And in the coming seasons, when she’s carving up Caribbean trades or rocketing across the Pacific, we’ll be watching closely. As for what’s next? Pat is already thinking about the next iteration. So are we.